Technological innovation of natural rubber crepe machine integrates power and transmission devices to improve work reliability and reduce production and maintenance costs

technical field

Natural rubber processing machinery, more specifically, natural rubber crepe sheet machine.

Background technology

Crepe sheet machine, a natural rubber processing machine, is an extremely important basic machinery in the natural rubber processing process. Its working characteristics are that the two rollers rotate relative to each other at different speeds. Therefore, when the rubber clump passes through the Crepe sheet machine, it is subjected to strong rolling and shearing effects, which not only dehydrates a lot and wrinkles the surface, but also plays a role in removing impurities inside the clump. At present, most rubber factories use old-fashioned power transmission methods for their crepe machines, where power is generated by an electric motor and transmitted to the high-speed shaft of the old style reducer after a single reduction through a V-belt. In the reducer, the power is reduced through multi-stage gear transmission and then transmitted to the half shaft coupling through the output shaft of the reducer, which is then transmitted to the working roller, thus completing the process of reducing and increasing torque power transmission for the entire machine. This type of transmission method has the following disadvantages and shortcomings:

1. The transmission chain is relatively long, and the problem caused by the long transmission chain is the entire system, greatly reducing the mechanical efficiency. For example, for a well tensioned V-belt, the efficiency is usually only about 90%, while for old style reducers with soft and medium hard tooth surfaces, the transmission efficiency is usually about 86%, resulting in a total efficiency of only 77% of the entire system, high mechanical loss, and low energy utilization efficiency;

2. There are many parts and components involved in the transmission, resulting in complex structures, multiple manufacturing processes, difficult assembly, and poor craftsmanship. At the same time, due to the large number of parts, there are more parts to be repaired and replaced, which not only increases the maintenance workload of the user unit, but also leads to an increase in maintenance costs. Roughly calculated, it can be seen that the transmission system of the old style crepe sheet machine has as many as 13 components and 22 fixed bolts, which requires a large amount of maintenance. The V-belt used for higher-level transmission needs to be replaced on average in 3 months. For rubber factories equipped with a large number of crepe sheet machines, the cost of replacing the V-belt in just one year is a considerable expense, let alone adding other parts;

3. The excessive number of components in the transmission system directly leads to a decrease in the reliability of the entire machine. As is well known, with the increase of components in a system, its reliability index is constantly decreasing. Low reliability means continuous shutdown and maintenance, and the transmission system happens to be the foundation of a mechanical work. While transmitting power, it also bears a huge load. Once frequent failures occur, it directly leads to production stoppage. From the statistical situation of actual use, all 13 components in the transmission system of the old-fashioned crepe machine have experienced failures, and even all 22 fixed bolts have experienced accidents of loosening and fracture;

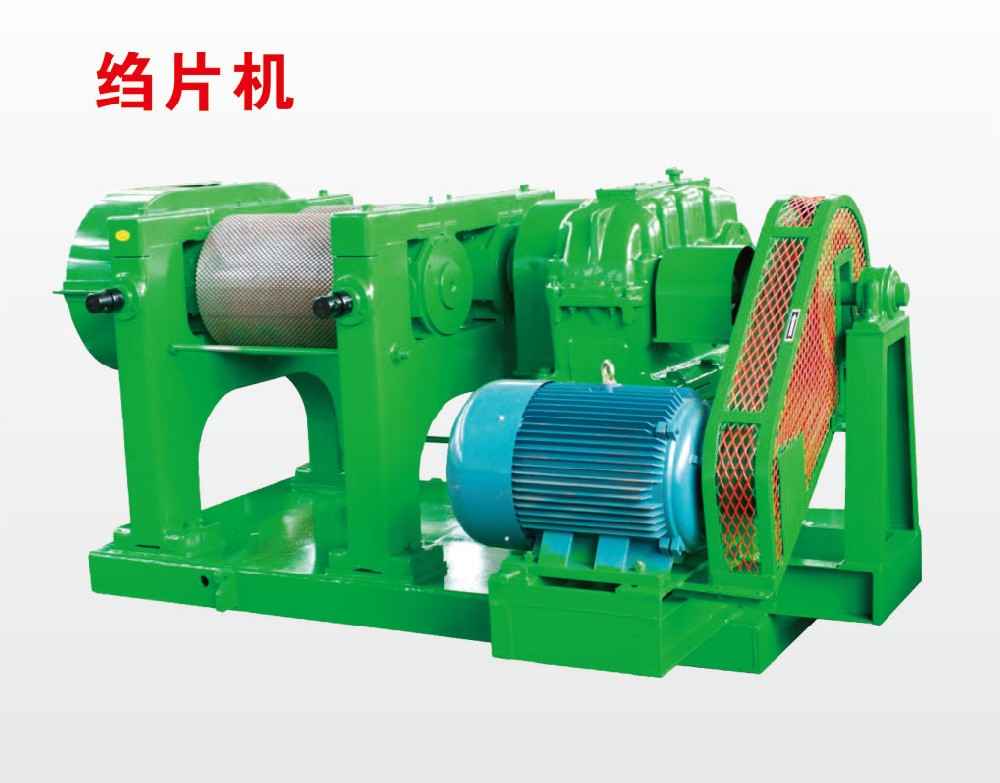

Guangdong Zhenghe Machinery Crease Machine, Natural Rubber Processing Equipment Crease Machine

Guangdong Zhenghe Machinery Crease Machine, Natural Rubber Processing Equipment Crease Machine

4. The old-fashioned crepe sheet machine, due to the use of a gearbox designed and standardized in the 1950s, appeared earlier and was limited by the technology and processing capacity at that time. This type of machine has many shortcomings, such as low box strength, poor internal component accuracy, poor load capacity, high noise, excessive vibration, and poor reliability. In practical use, it frequently malfunctions, cracks in the box, twists and breaks in the gear shaft, and teeth, not to mention problems such as excessive noise and severe vibration, all of which make users suffer.

The natural rubber crepe machine adopts an integrated gear reduction motor instead of the original belt and reducer, integrating the power device and transmission device into one, greatly simplifying the structure of the crepe machine. It not only shortens the transmission chain, but also reduces the number of parts in the transmission system, improves reliability during operation, and reduces production and maintenance costs.

A natural rubber crepe machine comprising a base and a roller pressing device, a reduction device, and a power device located on the base. The output end of the reduction device is connected to the roller pressing device, characterized in that the reduction device and the power device are integrated gear reduction motors, and the output end of the gear reduction motor is connected to the power input end of the roller pressing device by a coupling.

Pictures of crepe machine and crepe machine manufacturer

Specific implementation methods

The optimized modular design of the crepe machine has greatly shortened the transmission chain, resulting in a significant change. The efficiency has been improved, with a total transmission efficiency of 95%, which is much higher than the old model. In addition, the transmission components of the crepe machine have been reduced from thirteen to only three, and only eight fixing bolts are needed. At the same time, these three parts are designed for their full life, which means they do not need to be replaced during the 25000 hour service life. This makes the transmission system of the machine reach a maintenance free level, not only reducing maintenance costs, but also greatly improving the reliability of the machine. Based on the existing test data, the testing machine has worked at full load and high intensity for 2400 hours. After several hours of noise parameter evaluation, the testing machine was in good condition and showed no signs of increased clearance or increased wear, Compared with old-fashioned crepe machines, it has many advantages and significant advantages.

The above is the relevant content of Guangdong Zhenghe Machinery Network on improving the power and transmission device of the new natural rubber crepe machine technology to enhance the reliability of the crepe machine. If you would like to learn more about the exploration, design, production, installation, debugging, maintenance, and repair of rubber processing equipment and sugarcane sugar making equipment, please feel free to contact the business specialist of Guangdong Zhenghe Machinery Co., Ltd. via WeChat or phone. Zhenghe Machinery will warmly serve you. Service hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Website: http://www.gdzhjx.cn/html/jsjl/190.html

Reminder: Guangdong Zhenghe Machinery relies on new technologies, processes, and products for development, and the manufacturing of equipment strictly follows product manufacturing standards. To improve the quality of the product, the main components such as motors, gearboxes, electrical appliances, bearings, seals, etc. are purchased from imported parts or high-quality domestic brands. The company's processing equipment includes CNC gantry boring and milling, automatic cutting and forming machines, shot peening and painting production lines, and heat treatment production lines. The average technical level of enterprise employees is level 6, and the installation and after-sales service team is good, meeting the various needs of various customers. Customized mode, providing one-stop services for on-site exploration, design, production, production, installation, and debugging according to the actual needs of customers. Business consultation hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Copyright © www.gdzhjx.cn