The crepe machine is the main equipment of rubber processing enterprises. It is crucial to use the crepe machine correctly, maintain it carefully, and repair it in a timely manner to keep it in good condition and ensure smooth production. Firstly, it is recommended to implement a dedicated person responsible system for the maintenance and upkeep of the crepe machine. For equipment operated by a single person, the operator is the person in charge; Equipment and public equipment operated by multiple people shall be designated by workshop leaders to be responsible; Secondly, the operator of the crepe machine must comply with the equipment operating procedures, be familiar with the intact standards of the crepe machine, and achieve three good (management, use, and repair) and four good (use, maintenance, inspection, and troubleshooting). Overloading the crepe machine is strictly prohibited.

Four key points for maintenance and upkeep of crepe machine

1. The management personnel of the crepe machine clean it with clean water after work every day to ensure that the surface of the crepe machine is clean.

2. Add lubricating grease to the roller bearings of the crepe machine every eight hours. The oil of the new gearbox should be replaced once a month after use, and then every six months. If any deterioration is found in the crepe oil, it must be replaced immediately. The open gear and roller pitch adjustment device of the crepe machine are checked and lubricated once a week.

3. During the operation of the crepe machine, it is not allowed to disassemble the gear cover for maintenance.

4. Every year when cutting, it is necessary to perform comprehensive maintenance on the crepe machine. If there is excessive wear on the rollers and other spare parts of the crepe machine, they should be replaced in a timely manner.

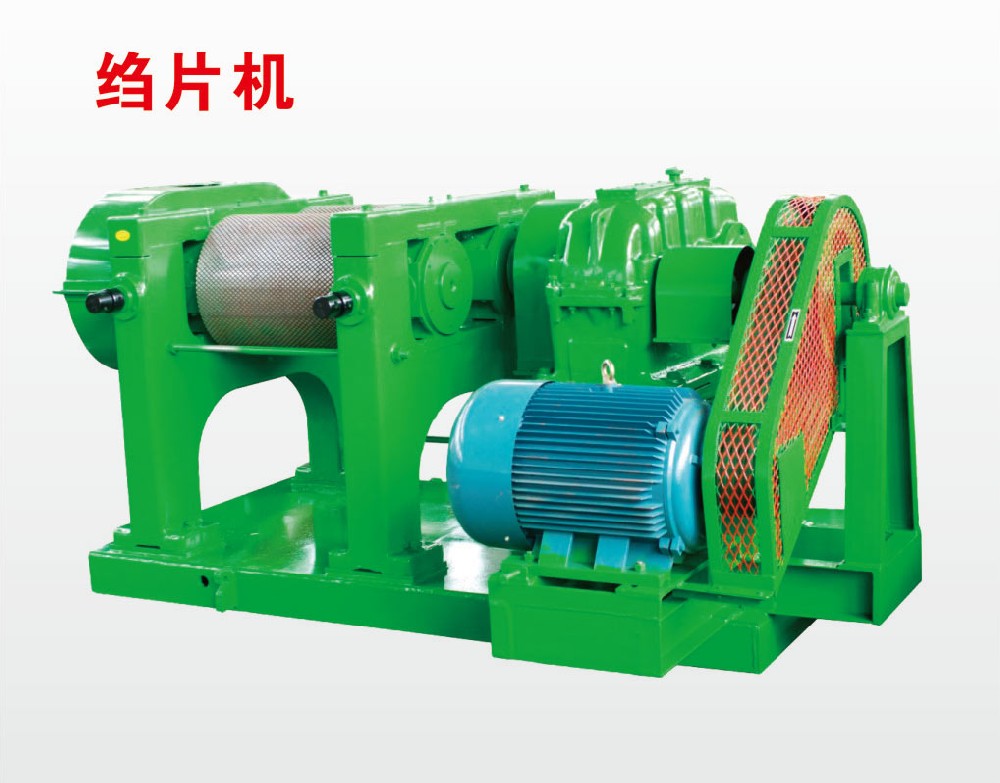

Natural rubber crepe machine

The above is the relevant content about the four key points of maintenance and upkeep for rubber crepe machines on Guangdong Zhenghe Machinery Network. If you would like to learn more about the exploration, design, production, production, installation, debugging, maintenance, and repair of rubber processing equipment and sugarcane sugar making equipment, please feel free to contact the business specialist of Guangdong Zhenghe Machinery Co., Ltd. via WeChat or phone. Zhenghe Machinery will warmly serve you. Service hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Website: http://www.gdzhjx.cn/html/jsjl/273.html

Reminder: Guangdong Zhenghe Machinery relies on new technologies, processes, and products for development, and the manufacturing of equipment strictly follows product manufacturing standards. To improve the quality of the product, the main components such as motors, gearboxes, electrical appliances, bearings, seals, etc. are purchased from imported parts or high-quality domestic brands. The company's processing equipment includes CNC gantry boring and milling, automatic cutting and forming machines, shot peening and painting production lines, and heat treatment production lines. The average technical level of enterprise employees is level 6, and the installation and after-sales service team is good, meeting the various needs of various customers. Customized mode, providing one-stop services for on-site exploration, design, production, production, installation, and debugging according to the actual needs of customers. Business consultation hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Copyright © www.gdzhjx.cn