The natural rubber we usually refer to is an elastic solid made from natural rubber latex collected from Brazilian rubber trees and processed through processes such as solidification and drying. Natural rubber is a natural polymer compound mainly composed of polyisoprene. Its rubber hydrocarbon (polyisoprene) content is over 90%, and it also contains small amounts of protein, fatty acids, sugar, and ash. Those engaged in the rubber industry know what natural rubber, synthetic rubber, recycled rubber, So, do you understand the processing process of natural rubber

Natural rubber undergoes three main steps from latex on trees to solid products: solidification, granulation (pressing), and drying; If it is made into concentrated latex, it mainly goes through processes such as centrifugation and concentration.

Natural rubber processing equipment manufacturer Guangdong Zhenghe Machinery

Natural rubber processing equipment manufacturer Guangdong Zhenghe Machinery

The rubber cut from the rubber tree can be divided into natural gel and pastoral latex. Natural gel can be pressed or granulated, and then dried to produce product cooling molding belt; The production process of natural rubber products after setting is the same for rural latex, but rural latex can produce concentrated latex products without setting sheep concentration.

The latex collected from rubber trees is diluted, acid cured, washed, then compressed, dried, and packaged to produce commercially available natural rubber.

Natural rubber can be made into concentrated latex, tobacco adhesive, standard adhesive, crepe adhesive, and so on according to different rubber making methods. Today, we will explain to you the processing process of milk standard glue in standard glue.

Natural rubber processing equipment manufacturer Guangdong Zhenghe Machinery

Natural rubber processing equipment manufacturer Guangdong Zhenghe Machinery

1. Centrifuge settler: After the rubber processing plant collects fresh latex glue, it is used to remove sediment, insects, ants, bark, leaves, etc. mixed from the outside of the latex, and then poured into a mixing tank for uniform mixing.

2. Latex setting tank: After stirring, while the latex glue is poured into the latex setting tank, acid is also poured in a certain proportion, mainly to accelerate the setting time of the latex glue.

3. Thin press: The solidified latex strips are thick and long, and a thin press is needed to press the latex strips into thin and elongated shapes and dehydrate them for subsequent processing.

4. Crepe film machine: After passing through a thinning machine, such as film, it is further pressed and dehydrated. At the same time, due to the diamond shaped patterns on the surface of the Crepe film machine and the relative movement between two rollers during operation, the speed difference between the rollers is used to pull the rubber sheets, achieving a honeycomb like rubber sheet.

5. Tearing and pelletizing machine: The tearing and pelletizing machine is used to crush crumpled rubber sheets that have been pressed into a honeycomb shape. The feeding roller is used to bite the rubber sheets, and the rotating blade ball inside the machine instantly cuts the rubber sheets into rubber particles.

6. The vibrating screen separates rubber particles and water, and dries them: Next, the water and rubber particles in the water tank are pumped together to the vibrating screen at a high place using a rubber pump. The vibrating screen will separate the water and rubber particles, and the separated water will be redirected back to the water tank. The rubber particles will fall into a V-shaped funnel, be loaded with a drying truck, and pushed to the drying line.

7. Hydraulic automatic packaging machine: After drying, use the hydraulic automatic packaging machine to pack the standard rubber bag of 33.33kg, and then cover it with film and bag to complete the process of packaging and storage.

The above is the relevant content of Guangdong Zhenghe Machinery Network on the processing process of milk standard rubber in natural rubber mud glue, miscellaneous glue, tobacco leaf glue standard rubber. If you want to learn more about rubber processing equipment, sugarcane sugar making equipment exploration, design, production, production, installation, commissioning, maintenance, and repair information, please feel free to contact the business specialist of Guangdong Zhenghe Machinery Co., Ltd. via WeChat or phone. Zhenghe Machinery will be enthusiastic about serving you. Service hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Website: http://www.gdzhjx.cn/html/jsjl/290.html

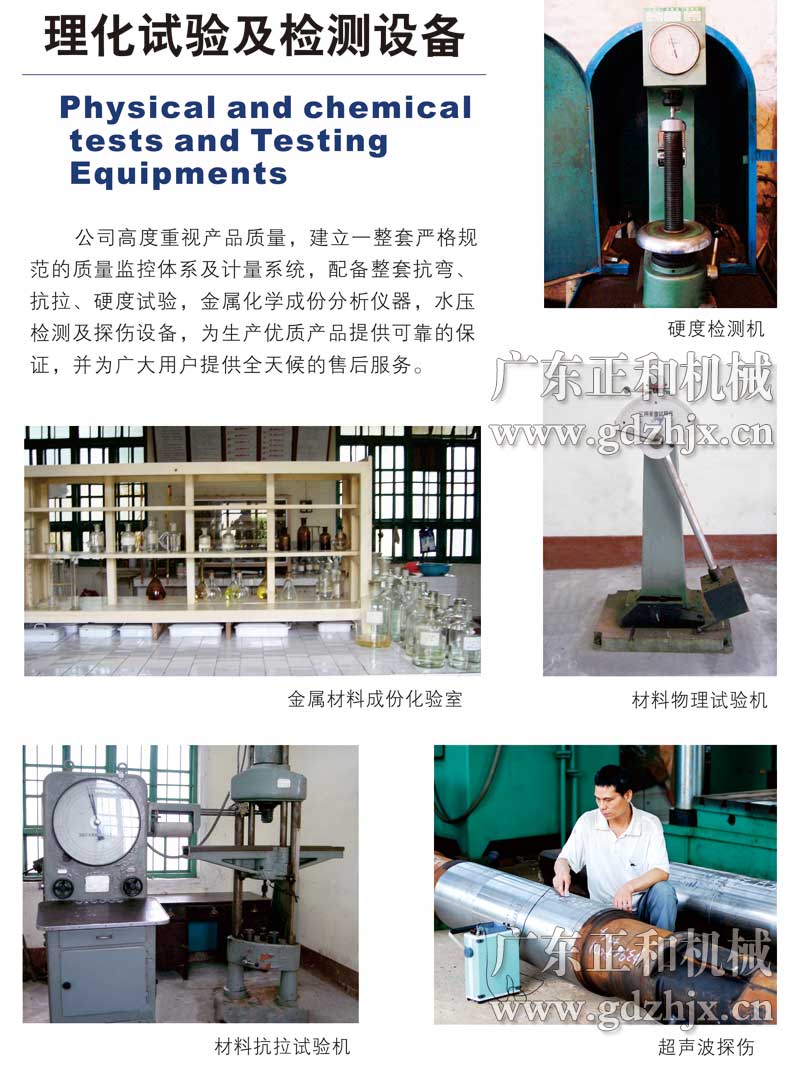

Reminder: Guangdong Zhenghe Machinery relies on new technologies, processes, and products for development, and the manufacturing of equipment strictly follows product manufacturing standards. To improve the quality of the product, the main components such as motors, gearboxes, electrical appliances, bearings, seals, etc. are purchased from imported parts or high-quality domestic brands. The company's processing equipment includes CNC gantry boring and milling, automatic cutting and forming machines, shot peening and painting production lines, and heat treatment production lines. The average technical level of enterprise employees is level 6, and the installation and after-sales service team is good, meeting the various needs of various customers. Customized mode, providing one-stop services for on-site exploration, design, production, production, installation, and debugging according to the actual needs of customers. Business consultation hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Copyright © www.gdzhjx.cn