Before the rubber packaging machine leaves the factory, Zhenghe Machinery will inform customers how to safely use the hydraulic automatic packaging machine when using it, as well as what issues to pay attention to during the use of the packaging machine. However, even so, before using the hydraulic packaging machine, in addition to paying attention to the various operating instructions given by the rubber packaging machine manufacturer, you still need to carefully read the product manual of the hydraulic packaging machine to reduce various problems that may occur during the production process. In addition, customers need to pay attention to some key working points of the rubber packaging machine during use, and also pay attention to regular maintenance. This is very important for extending the service life of the rubber packaging machine and ensuring the long-term stable operation of the hydraulic packaging machine.

Rubber processing equipment, natural rubber initial processing equipment, rubber processing equipment manufacturer

Zhenghe Machinery, Rubber Processing Equipment, Natural Rubber Initial Processing Equipment, Rubber Processing Equipment Manufacturer

There are many safety precautions to be taken when using a rubber hydraulic packaging machine. Users should operate the machine correctly, pay attention to maintenance, and always remember the safe operation process.

Zhenghe Mechanical Rubber Packaging Machine, now I would like to emphasize again the precautions for hydraulic packaging machine operation and safety production.

1. Before replacing the hydraulic packaging machine, it is necessary to wear work clothes, fasten the cuffs, and keep the hem of the top not open. It is not allowed to put on or take off clothes or wrap them around the body next to the running machine tool to prevent machine injuries. It is necessary to wear safety and labor protection equipment,

2. Hydraulic packaging machine operators must be familiar with the main structure, performance, and usage methods of the packaging machine.

3. Hydraulic packaging machine operators must undergo training and master the performance and operation techniques of hydraulic packaging machines before they can operate independently.

4. Before starting the packaging machine, all kinds of debris on the equipment should be cleaned and any dirt on the hydraulic press should be wiped clean.

5. The installation, maintenance, and upkeep of hydraulic presses must be carried out under power-off conditions, and touching buttons and handles is prohibited.

6. Assemble the upper and lower molds for centering, adjust the mold clearance, and do not allow unilateral deviation from the center. After confirmation, press the mold again.

7. Before operating the hydraulic packaging machine, the first thing to check is whether the oil level in the oil tank is sufficient, whether the oil pump sound is normal, and whether there is any leakage in the hydraulic unit, pipelines, joints, and pistons.

8. Start the hydraulic packaging machine for pressure testing, check whether the pressure of the packaging machine reaches the working pressure, whether the action of the packaging machine is normal and reliable, and whether there is any leakage.

9. When the pressure plate of the packaging machine slides up and down, it is strictly prohibited to extend hands and heads into the working parts of the equipment.

10. It is strictly prohibited to strike, stretch, weld, bend, or twist the packaging machine while applying pressure.

11. Smoking, welding, and hot work are not allowed around the hydraulic press packaging machine, and flammable and explosive materials are not allowed to be stored. Take fire prevention measures.

12. After the rubber hydraulic packaging machine is completed, the power should be cut off, the hydraulic rod of the press should be wiped clean, lubricating oil should be added, and the workpiece should be cleaned and placed

13. If any abnormal operation of the hydraulic packaging machine is found during use, the power should be immediately cut off and the machine should be shut down for inspection.

Keywords: Hydraulic packaging machine operating procedures Rubber processing machinery Hydraulic packaging machine Work safety

The above is the relevant content of Guangdong Zhenghe Machinery Network about the safety factors that need to be considered when using hydraulic packaging machines and automatic packaging machines. If you want to learn more about the exploration, design, production, production, installation, debugging, maintenance, and repair of rubber processing equipment and sugarcane sugar making equipment, please feel free to contact the business specialist of Guangdong Zhenghe Machinery Co., Ltd. via WeChat or phone. Zhenghe Machinery will be enthusiastic about serving you. Service hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Website: http://www.gdzhjx.cn/html/jsjl/253.html

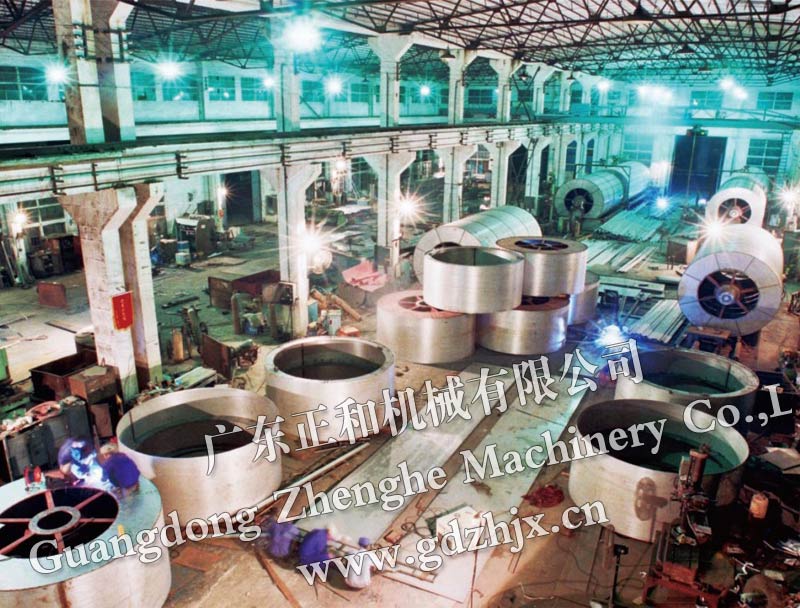

Reminder: Guangdong Zhenghe Machinery relies on new technologies, processes, and products for development, and the manufacturing of equipment strictly follows product manufacturing standards. To improve the quality of the product, the main components such as motors, gearboxes, electrical appliances, bearings, seals, etc. are purchased from imported parts or high-quality domestic brands. The company's processing equipment includes CNC gantry boring and milling, automatic cutting and forming machines, shot peening and painting production lines, and heat treatment production lines. The average technical level of enterprise employees is level 6, and the installation and after-sales service team is good, meeting the various needs of various customers. Customized mode, providing one-stop services for on-site exploration, design, production, production, installation, and debugging according to the actual needs of customers. Business consultation hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Copyright © www.gdzhjx.cn