Guangdong Zhenghe Machinery is a manufacturer of rubber crushers, providing prices, technical consultation, and quotation for rubber crushers. Welcome to inquire by phone.

Rubber crusher, also known as rubber crusher, rubber breaker, rubber breaker, rubber pellet cutter, and rubber pellet pre crusher. The rubber crusher is composed of a body, a knife shaft, a moving knife, a fixed knife, an electric motor, a reducer, a hopper, and so on. The transmission of the rubber crusher is transmitted from the electric motor to the transition shaft, which is then transmitted to the reducer to directly drive the rotation of the knife shaft. A moving knife disc is installed on the knife shaft, and fixed knives are respectively installed in the front and back of the machine body. When the mixed rubber block is loaded from the hopper, the rotating moving knife disc breaks the mixed rubber block. The broken rubber material flows into the water tank through the inclined plate of the machine body, thus achieving the purpose of crushing and cleaning.

Rubber crusher, rubber crusher, Zhenghe Machinery

Rubber crusher, rubber crusher, Zhenghe Machinery

Zhenghe Mechanical Rubber Crusher is used in the initial processing of natural rubber to crush, clean and remove impurities from the rubber. It is an equipment for producing No. 20 standard rubber.

No. 20 rubber is one of the mainstream varieties of natural rubber. Rubber is mainly divided into natural rubber and synthetic rubber. Natural rubber refers to the elastic solid material made from natural latex collected from Brazilian rubber trees, processed through solidification, drying, and other processes. Synthetic rubber is a highly elastic polymer synthesized artificially, also known as synthetic elastomer, which broadly refers to rubber synthesized by chemical methods to distinguish it from natural rubber produced from rubber trees.

Natural rubber has excellent characteristics such as resilience, insulation, water resistance, and plasticity. After appropriate treatment, it also has valuable properties such as oil resistance, acid resistance, alkali resistance, heat resistance, cold resistance, pressure resistance, and wear resistance, making it widely used. Tires, rubber hoses, tape, and shoe materials are the main downstream applications of natural rubber. Among them, about 70% of natural rubber worldwide is used in tire manufacturing, 10% is used for rubber tubing, 10% is used for shoe materials, and 10% is used for other rubber products. About 80% of the natural rubber used in tire manufacturing is grade 20 rubber; The use of No. 20 rubber has become a major indicator of the level of technology and process in the tire industry. Almost all of the No. 20 rubber is used to produce tires.

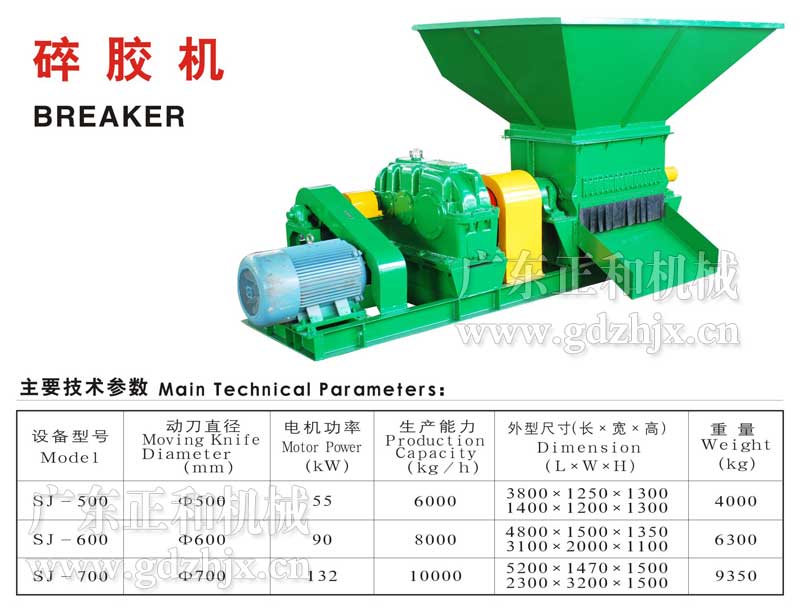

Rubber crusher manufacturer, Zhenghe Machinery provides you with detailed parameters of rubber crusher products, real-time quotes for rubber crushers, price trends for rubber crushers, high-quality wholesale of rubber crushers, and supply of rubber crushers.

The above is the relevant content about rubber crushers, crushers, and No. 20 standard rubber crushers and crushers on Guangdong Zhenghe Machinery Network. If you would like to learn more about rubber processing equipment, sugarcane sugar making equipment exploration, design, production, production, installation, commissioning, maintenance, and repair, please feel free to contact the business specialist of Guangdong Zhenghe Machinery Co., Ltd. via WeChat or phone. Zhenghe Machinery will warmly serve you. Service hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Website: http://www.gdzhjx.cn/html/jsjl/266.html

Reminder: Guangdong Zhenghe Machinery relies on new technologies, processes, and products for development, and the manufacturing of equipment strictly follows product manufacturing standards. To improve the quality of the product, the main components such as motors, gearboxes, electrical appliances, bearings, seals, etc. are purchased from imported parts or high-quality domestic brands. The company's processing equipment includes CNC gantry boring and milling, automatic cutting and forming machines, shot peening and painting production lines, and heat treatment production lines. The average technical level of enterprise employees is level 6, and the installation and after-sales service team is good, meeting the various needs of various customers. Customized mode, providing one-stop services for on-site exploration, design, production, production, installation, and debugging according to the actual needs of customers. Business consultation hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Copyright © www.gdzhjx.cn