The hydraulic sugarcane clamping device of the sugarcane flipper is a device that compresses and fixes the sugarcane in the upper part of the carriage during the unloading process of the sugarcane truck above the main body of the flipper, avoiding the problem of sugarcane falling off during the lifting process of the flipper, and thus avoiding the problem of sugarcane falling disorderly. The existing flipper is a device that facilitates the auxiliary unloading of materials on the car, but during the sugarcane unloading process, it often occurs that the sugarcane in the upper part of the car falls off during the lifting process of the flipper, causing the sugarcane to slide irregularly and also causing damage. The position of the sugarcane being squeezed cannot be adjusted well, and during the process of pressurizing the sugarcane, it is difficult to adjust the position of the sugarcane. The problem of sugarcane collapse often occurs in the middle, therefore, We propose a hydraulic sugarcane clamping device for sugarcane flipping machines to solve the above problems.

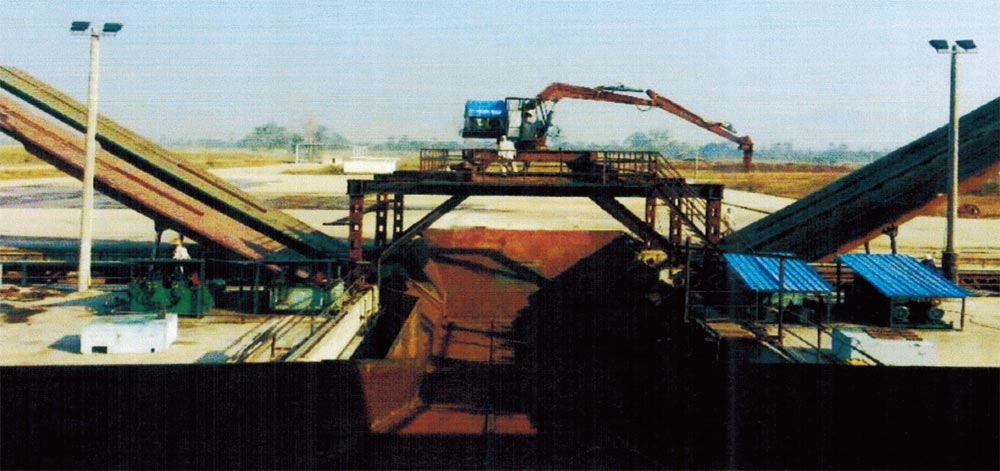

Sugarcane flipper, flipper, sugarcane flipper conveyor, sugarcane conveyor, sugarcane flipper manufacturer, sugarcane flipper pictures

Guangdong Zhenghe Machinery - a professional sugarcane flipper manufacturer, with pictures of sugarcane flippers

Technical implementation elements:

The purpose of a sugarcane flipper is to provide a hydraulic sugarcane clamping device for the sugarcane flipper, in order to solve the problem that the current market flippers proposed in the background technology cannot squeeze and fix the sugarcane on the upper part of the car, and cannot adjust it according to its position.

To achieve the above objectives, the present utility model provides the following technical solution: a hydraulic cane clamping device for a sugarcane flipping machine, comprising a flipping machine body and an electric motor. A clamp bracket is set above the flipping machine body, and a hydraulic cylinder is installed in the middle of the clamp bracket. A clamp assembly is set above the clamp bracket, and the upper part of the hydraulic cylinder is connected to the clamp through a support bracket. A pressure plate is set at the top of the clamp plate, and a hydraulic cylinder is installed below the pressure plate, and a clamp plate is fixedly installed at the bottom of the hydraulic cylinder. The right side of the electric motor is connected to the sliding sleeve through a rotating shaft, and a rolling gear is fixed externally on the rotating shaft.

Compared with the existing technology, the beneficial effect of this utility model is that the hydraulic sugarcane clamping device of the sugarcane flipper is equipped with a clamping plate assembly, which can effectively squeeze the sugarcane above the car, avoiding the problem of the sugarcane falling off during the lifting process of the flipper. The pressure plate forms a lifting structure through a hydraulic cylinder, which allows the pressure plate to squeeze the sugarcane above it according to the height of the upper sugarcane, so that the middle sugarcane will not jump out and fall off from the middle under the squeezing effect of the two side clamping plates. At the same time, the entire upper sugarcane can be better fixed, so that when the flipper rises to a certain height for unloading, the sugarcane will not scatter. The installation of the motor allows the rolling gears to move inside the sliding sleeve, Furthermore, it drives the sliding sleeve to move inside the main body of the flipper, thereby driving the clamp bracket to move at the bottom of the flipper body, allowing the entire device to move well above the flipper body and increasing the compression range of sugarcane, making the entire sugarcane clamping device more widely used.

Specific implementation methods

Technical features:

Technical Summary

A hydraulic sugarcane flipping machine clamping device, comprising a flipping machine body and a motor. A clamping plate bracket is provided above the flipping machine body, and a hydraulic cylinder is installed in the middle of the clamping plate bracket. A clamping plate assembly is provided above the clamping plate bracket, and the hydraulic cylinder is connected to the clamping plate through a support frame. The top of the clamping plate is provided with a pressure plate, and a hydraulic cylinder is installed below the pressure plate. The bottom of the hydraulic cylinder is fixedly installed with a clamping plate. The right side of the motor is connected to the sliding sleeve through a rotating shaft, and a rolling gear is fixed externally on the rotating shaft. The hydraulic sugarcane flipper is equipped with a clamp assembly, which can effectively squeeze the sugarcane above the car, avoiding the problem of falling during the lifting process of the flipper. The pressure plate forms a lifting structure through the hydraulic cylinder, which prevents the sugarcane in the middle from jumping out and falling under the squeezing effect of the two side clamps.

The above is the relevant content of Guangdong Zhenghe Machinery Network about the production method of a hydraulic sugarcane clamping device for sugarcane flipping machines. If you want to learn more about rubber processing equipment and sugarcane sugar making equipment exploration, design, production, installation, debugging, maintenance, and repair, please feel free to contact the business specialist of Guangdong Zhenghe Machinery Co., Ltd. via WeChat or phone. Zhenghe Machinery will be enthusiastic about serving you. Service hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Website: http://www.gdzhjx.cn/html/jsjl/189.html

Reminder: Guangdong Zhenghe Machinery relies on new technologies, processes, and products for development, and the manufacturing of equipment strictly follows product manufacturing standards. To improve the quality of the product, the main components such as motors, gearboxes, electrical appliances, bearings, seals, etc. are purchased from imported parts or high-quality domestic brands. The company's processing equipment includes CNC gantry boring and milling, automatic cutting and forming machines, shot peening and painting production lines, and heat treatment production lines. The average technical level of enterprise employees is level 6, and the installation and after-sales service team is good, meeting the various needs of various customers. Customized mode, providing one-stop services for on-site exploration, design, production, production, installation, and debugging according to the actual needs of customers. Business consultation hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Copyright © www.gdzhjx.cn