Instructions for Operating, Using, Cleaning, Maintaining, Maintaining, Stopping, and Repairing Rubber Crushers

1. Clean the rubber crusher with clean water after work every day to ensure that the surface of the crusher is clean.

2. Check the running wear of the two bearings of the rubber crusher every six months. If the wear or heat is severe, it must be replaced.

3. The fixed and fixed blades of the rubber crusher are removed and regraded every three months, and replaced every six months to ensure light and fast cutting of the rubber material.

4. The rubber crusher must be maintained in a fully stopped state and a warning sign must be hung at the power switch to prevent accidental movement by others

5. Every year when cutting, it is necessary to perform comprehensive maintenance on the rubber crusher. The cutting door and cutting edge should be re welded with wear-resistant welding rods. If the cutting edge is worn too much, please replace it in a timely manner.

Rubber crusher

Rubber crusher

[Purpose of rubber crusher]

Rubber crusher, also known as rubber crusher, rubber breaker, rubber breaker, rubber pellet cutter, rubber pellet pre crusher, rubber crusher

[Purpose of rubber crusher]

The rubber crusher is used in the initial processing of natural rubber to crush, clean and remove impurities from the rubber. It is an equipment for producing No. 20 standard rubber.

[Structure and working principle of rubber crusher]

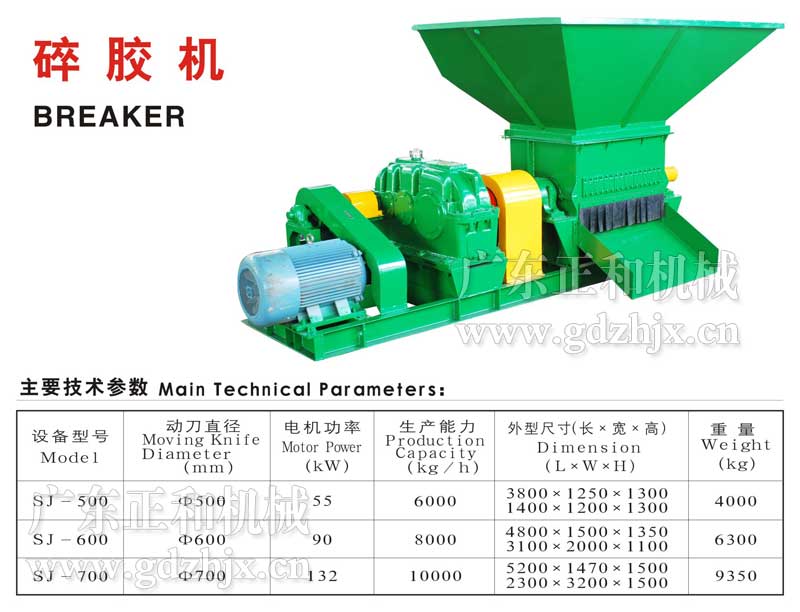

The rubber crushing machine is composed of a body, a knife shaft, a moving knife, a fixed knife, an electric motor, a reducer, a hopper, and so on.

The transmission of the rubber crusher is transmitted from the electric motor to the transition shaft, which is then transmitted to the reducer to directly drive the rotation of the knife shaft. A moving knife disc is installed on the knife shaft, and fixed knives are respectively installed in the front and back of the machine body. When the mixed rubber block is loaded from the hopper, the rotating moving knife disc breaks the mixed rubber block. The broken rubber material flows into the water tank through the inclined plate of the machine body, thus achieving the purpose of crushing and cleaning.

Rubber crusher model

SJ-50B

The diameter of the rubber shredder cutterhead

ф500mm

Rotational speed of the rubber crushing machine cutterhead

40r/min

Rubber crusher reducer model

ZSY280-31.5-55II

Rubber crusher reducer transmission ratio

thirty-one point five

Rubber crusher motor model

Y250M-4

Rubber crusher motor power

55KW

Production capacity of rubber crusher (dry rubber)

2000kg/h

Picture of rubber crusher

Rubber crusher, rubber crusher, rubber breaker

The above is the relevant content about the operation, use, cleaning, maintenance, maintenance, inspection and repair of rubber crushers on Guangdong Zhenghe Machinery Network. If you want to learn more about the exploration, design, production, production, installation, commissioning, maintenance, and repair of rubber processing equipment and sugarcane sugar making equipment, please feel free to contact the business specialist of Guangdong Zhenghe Machinery Co., Ltd. via WeChat or phone. Zhenghe Machinery will warmly serve you. Service hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Website: http://www.gdzhjx.cn/html/jsjl/276.html

Reminder: Guangdong Zhenghe Machinery relies on new technologies, processes, and products for development, and the manufacturing of equipment strictly follows product manufacturing standards. To improve the quality of the product, the main components such as motors, gearboxes, electrical appliances, bearings, seals, etc. are purchased from imported parts or high-quality domestic brands. The company's processing equipment includes CNC gantry boring and milling, automatic cutting and forming machines, shot peening and painting production lines, and heat treatment production lines. The average technical level of enterprise employees is level 6, and the installation and after-sales service team is good, meeting the various needs of various customers. Customized mode, providing one-stop services for on-site exploration, design, production, production, installation, and debugging according to the actual needs of customers. Business consultation hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Copyright © www.gdzhjx.cn