The use of rubber crusher

1. Before using the rubber crusher for the first time after installing it, it is necessary to inspect the rubber crusher and confirm whether all connection parts are loose. Each lubrication point is filled with lubricating grease, and the gearbox is filled with oil to the oil line.

2. Rotate the rubber crusher belt by hand and check whether the blade shaft runs smoothly, whether there is obvious axial movement of the blade shaft, whether there are obstacles in the crushing chamber, and ensure that all moving parts are free of abnormal vibration and noise.

3. Open the water inlet valve of the rubber crusher, and then jog to check whether the rotation direction of the knife shaft is correct and whether the moving parts are experiencing abnormal vibration and noise. The temperature rise of the bearing position shall not exceed 60 ° C. Check if the belt tension is moderate and consistent. Whether each electrical component is sensitive; The no-load test run must be continuous for at least 2 hours.

4. First, conduct limited feeding and trial production, and check whether all parts of the machine are operating normally, and whether there are any abnormal vibrations and noises. Measure whether the working current of the motor exceeds the rated current value, whether the fluctuation is too large, and whether the blade shaft speed has decreased. If the trial run lasts for more than 2 hours and meets the requirements, it can be put into production.

5. Always pay attention to the feeding situation of the crushed rubber material when using the shredder. If any debris is brought into the chassis along with the adhesive material and gets stuck in the glue crusher, causing the overcurrent switch to break or sudden power outage, there may be glue stacking phenomenon. The chassis should be immediately checked for debris, and then reversed to clean the chassis. If the safety pin breaks, it should be replaced immediately.

6. When encountering an emergency situation, first turn off the emergency stop switch of the rubber crusher.

Rubber crusher

Rubber crusher

[Purpose of rubber crusher]

Rubber crusher, also known as rubber crusher, rubber breaker, rubber breaker, rubber pellet cutter, rubber pellet pre crusher, rubber crusher

[Purpose of rubber crusher]

The rubber crusher is used in the initial processing of natural rubber to crush, clean and remove impurities from the rubber. It is an equipment for producing No. 20 standard rubber.

[Structure and working principle of rubber crusher]

The rubber crushing machine is composed of a body, a knife shaft, a moving knife, a fixed knife, an electric motor, a reducer, a hopper, and so on.

The transmission of the rubber crusher is transmitted from the electric motor to the transition shaft, which is then transmitted to the reducer to directly drive the rotation of the knife shaft. A moving knife disc is installed on the knife shaft, and fixed knives are respectively installed in the front and back of the machine body. When the mixed rubber block is loaded from the hopper, the rotating moving knife disc breaks the mixed rubber block. The broken rubber material flows into the water tank through the inclined plate of the machine body, thus achieving the purpose of crushing and cleaning.

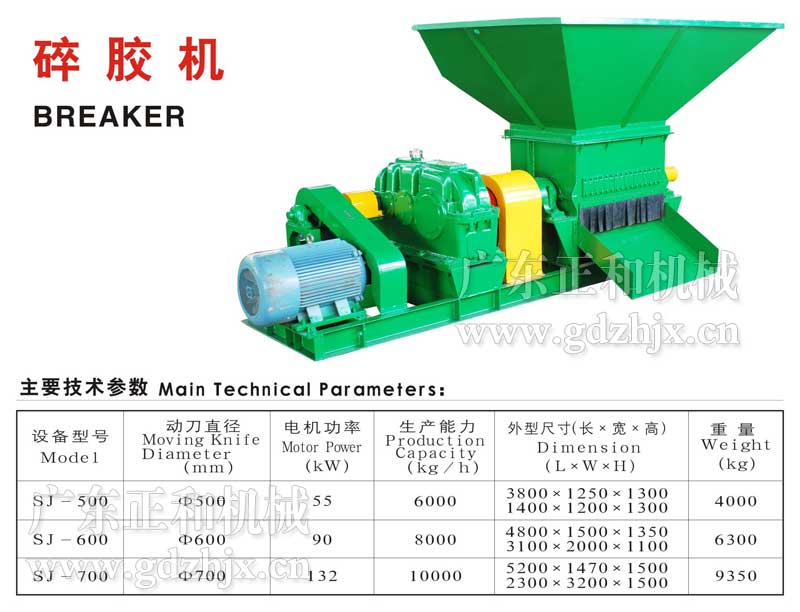

Rubber crusher model

SJ-50B

The diameter of the rubber shredder cutterhead

ф500mm

Rotational speed of the rubber crushing machine cutterhead

40r/min

Rubber crusher reducer model

ZSY280-31.5-55II

Rubber crusher reducer transmission ratio

thirty-one point five

Rubber crusher motor model

Y250M-4

Rubber crusher motor power

55KW

Production capacity of rubber crusher (dry rubber)

2000kg/h

Picture of rubber crusher

Rubber crusher, rubber crusher, rubber breaker

The above is the information about the use, maintenance, and upkeep of rubber crushers on Guangdong Zhenghe Machinery Network, including rubber crushers and rubber crushers. If you would like to learn more about the exploration, design, production, production, installation, commissioning, maintenance, and repair of rubber processing equipment and sugarcane sugar making equipment, please feel free to contact the business specialist of Guangdong Zhenghe Machinery Co., Ltd. via WeChat or phone. Zhenghe Machinery will warmly serve you. Service hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Website: http://www.gdzhjx.cn/html/jsjl/274.html

Reminder: Guangdong Zhenghe Machinery relies on new technologies, processes, and products for development, and the manufacturing of equipment strictly follows product manufacturing standards. To improve the quality of the product, the main components such as motors, gearboxes, electrical appliances, bearings, seals, etc. are purchased from imported parts or high-quality domestic brands. The company's processing equipment includes CNC gantry boring and milling, automatic cutting and forming machines, shot peening and painting production lines, and heat treatment production lines. The average technical level of enterprise employees is level 6, and the installation and after-sales service team is good, meeting the various needs of various customers. Customized mode, providing one-stop services for on-site exploration, design, production, production, installation, and debugging according to the actual needs of customers. Business consultation hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Copyright © www.gdzhjx.cn