What are the main equipment used in the sugar production process of sugarcane?

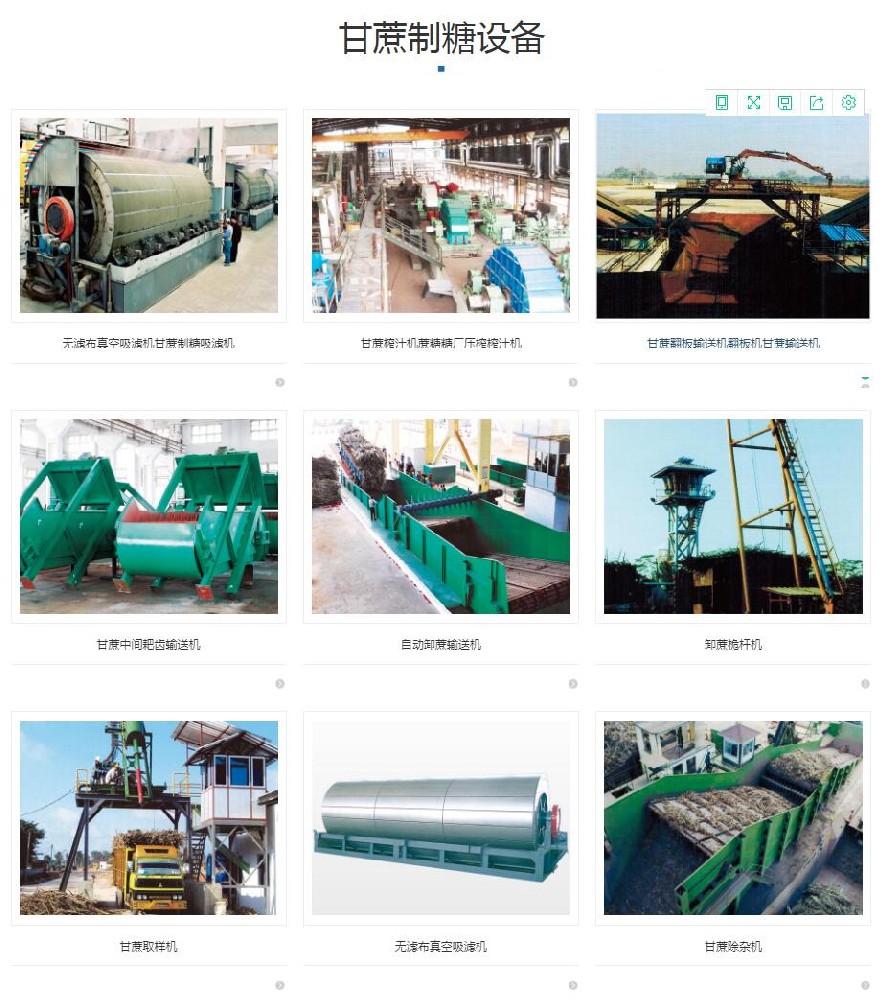

The main equipment required in the sugar production process of sugarcane is the harvester, weighing table, feeding table, conveying machine, iron remover, sugarcane crushing machinery, cutting machine, tearing machine, grinder, press, and filter.

Price of sugarcane sugar making equipment wholesale manufacturer Guangdong Zhenghe Machinery

Cane Sugar Making Equipment Pictorial_Price_Wholesale_Manufacturer - Guangdong Zhenghe Machinery

The sugarcane sugar production process includes:

① Juice extraction. The sugarcane stalks are cut by a group of rapidly rotating knives on the conveyor belt in the squeezing workshop, then crushed by a tearing machine, and then continuously squeezed out sugarcane juice through 4-7 three roll presses. The sugarcane juice flowing out from the tearing machine and * * squeezing machine is called mixed juice.

② Pure. The mixed juice contains various non sugar components and must be purified before further processing. The widely used methods include lime method and sulfite purification method. The lime method is often used to manufacture sugarcane raw sugar.

③ Evaporation. After purification, the clear juice is preheated and placed in a vertical cylindrical evaporator with a heating drum inside. Hot steam is introduced to heat the sugar juice and evaporate and concentrate it, becoming a syrup that can be boiled and crystallized.

④ Boiling sugar, assisting crystallization, and separating honey. Draw the syrup into the sugar boiling jar and further heat and evaporate under vacuum. After evaporating and concentrating to a certain degree of supersaturation, sugar powder can be added for crystallization. Then continue to add syrup or molasses continuously, gradually growing the grains until a sugar paste with crystal content and mother liquor concentration that meet the requirements is formed in the entire tank, and it can be put into the tank. The released sugar paste flows into the honey separator through the crystal aid tank, and the mother liquor is separated by centrifugal force. The crystalline sugar left in the machine is washed with water and discharged to dry before becoming the finished sugar product. The mother liquor separated, i.e. molasses, can also be boiled and separated for the second and third time.

⑤ Refinement of raw sugar. First, add molasses to the raw sugar juice for washing, then separate it again with a centrifuge and wash the grains. Then, add a small amount of lime milk and filter it with diatomaceous earth; Then obtain refined sugar solution through decolorization.

[Sugarcane Sugar Making Equipment] Sugarcane Sugar Making Equipment Price Wholesale Manufacturer - Guangdong Zhenghe Machinery

Guangdong Zhenghe Machinery sugarcane sugar making equipment channel provides you with information on the purchase and sale of sugarcane sugar making equipment manufacturers, as well as information on wholesale suppliers of sugarcane sugar making equipment. If you want to learn more about the prices of sugarcane sugar making equipment and the introduction of merchants, please go to Guangdong Zhenghe Machinery sugarcane sugar making equipment channel

The above is the relevant content of Guangdong Zhenghe Machinery Network on the price wholesale manufacturer survey, design, production, installation, and commissioning of sugarcane sugar making equipment. If you would like to learn more about rubber processing equipment, sugarcane sugar making equipment exploration, design, production, production, installation, commissioning, maintenance, and repair, please feel free to contact the business specialist of Guangdong Zhenghe Machinery Co., Ltd. via WeChat or phone. Zhenghe Machinery will warmly serve you. Service hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Website: http://www.gdzhjx.cn/html/jsjl/200.html

Reminder: Guangdong Zhenghe Machinery relies on new technologies, processes, and products for development, and the manufacturing of equipment strictly follows product manufacturing standards. To improve the quality of the product, the main components such as motors, gearboxes, electrical appliances, bearings, seals, etc. are purchased from imported parts or high-quality domestic brands. The company's processing equipment includes CNC gantry boring and milling, automatic cutting and forming machines, shot peening and painting production lines, and heat treatment production lines. The average technical level of enterprise employees is level 6, and the installation and after-sales service team is good, meeting the various needs of various customers. Customized mode, providing one-stop services for on-site exploration, design, production, production, installation, and debugging according to the actual needs of customers. Business consultation hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Copyright © www.gdzhjx.cn