For the convenience of those who have just entered or want to have a deeper understanding of the natural rubber industry and the natural rubber production process, today we bring you natural rubber raw rubber crepe sheets.

In the previous video, we introduced the crushing of raw rubber. After crushing and cleaning, the raw rubber still carries some impurities. The purpose of using a crepe machine to crush and clean natural rubber materials. The basic process of the crepe sheet machine is to roll and shear the material through two crepe sheets, making the material thin and wrinkled on the surface. At the same time, it can also remove impurities from the material, achieving the purpose of cleaning. Watch the crepe process shown in the video.

Natural rubber initial processing machinery crepe sheet

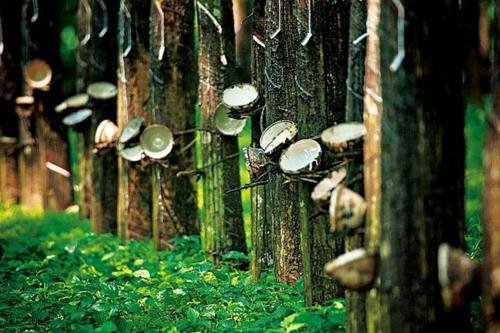

How did natural rubber come about?

A crepe machine usually consists of three parts. They are a pair of diamond patterned rollers rotating in opposite directions, a frame, and a transmission system. Raw rubber crushing usually requires five to six rounds of crepe machine for creping. Crepe sheet and its use of roller pressing mechanism with opposite movement of front and rear rollers make the rubber material thin and flat, and discharge the moisture and impurities of the rubber material. Due to the speed difference between the front and rear rollers, the rubber material is made into a honeycomb like crepe film on the surface.

Natural rubber initial processing machinery - Crepe sheet machine

How did natural rubber come about

The glue after being wrinkled will become more regular, and then it will be transmitted to the oven through a conveyor belt, and the heating will be more uniform in the subsequent baking.

The above is the relevant content about the natural rubber raw rubber crepe sheet machine in Guangdong Zhenghe Machinery Network, which produces rolling and shearing of materials, resulting in material thinning and surface wrinkling. If you would like to learn more about rubber processing equipment and sugarcane sugar making equipment exploration, design, production, production, installation, commissioning, maintenance, and repair, please feel free to contact the business specialist of Guangdong Zhenghe Machinery Co., Ltd. via WeChat or phone. Zhenghe Machinery will warmly serve you. Service hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Website: http://www.gdzhjx.cn/html/jsjl/182.html

Reminder: Guangdong Zhenghe Machinery relies on new technologies, processes, and products for development, and the manufacturing of equipment strictly follows product manufacturing standards. To improve the quality of the product, the main components such as motors, gearboxes, electrical appliances, bearings, seals, etc. are purchased from imported parts or high-quality domestic brands. The company's processing equipment includes CNC gantry boring and milling, automatic cutting and forming machines, shot peening and painting production lines, and heat treatment production lines. The average technical level of enterprise employees is level 6, and the installation and after-sales service team is good, meeting the various needs of various customers. Customized mode, providing one-stop services for on-site exploration, design, production, production, installation, and debugging according to the actual needs of customers. Business consultation hotline: 13824803990, 0759-3363353; WeChat ID: 13828211689

Copyright © www.gdzhjx.cn